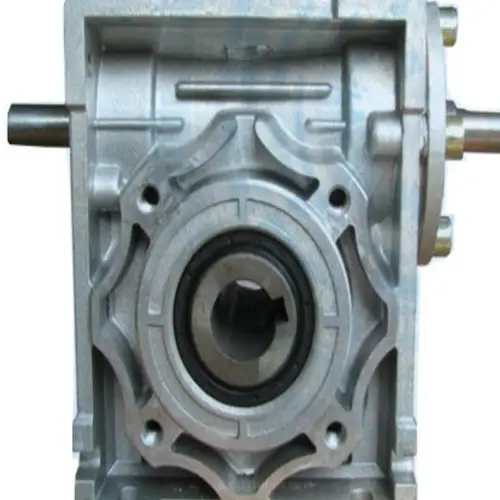

China Wholesaler Nrv Worm Geared Reducer Wholesaler: A Comprehensive Power Transmission Solution

Product Description

The RV series is a versatile range of worm gear reducers that offer exceptional performance and reliability. With various sizes, input options, and power capacities, these gear reducers are suitable for a wide range of industrial applications. Here are some key characteristics of the RV series:

- RV – Sizes: 150

- Input Options: with input shaft, With Square flange, With Input Flange

- Input Power: 0.06 to 11 kW

- RV-Size: from 030 to 105 in die-cast aluminum alloy body and over 110 in cast iron

- Ratios: between 5 and 100

- Max torque: 1550 N.m

- Admissible output radial loads: max 8771 N

- Aluminum units are supplied complete with synthetic oil and allow for universal mounting positions, with no need to modify lubricant quantity

- Worm wheel: Copper (KK Cu)

- Loading capacity in accordance with: ISO 9001:2015/GB/T 19001-2016

- Size 030 and over are painted with RAL 5571 blue

- Worm gear reducers are available with different combinations: NMRV+NMRV, NMRVpower+NMRV, JWB+NMRV

- NMRV, NRV+VS, NMRV+AS, NMRV+VS, NMRV+F

- Options: torque arm, output flange, viton oil seals, low/high-temperature oil, filling/drain/breather/level plug, Small gap

Basic models can be applied to a wide range of power reduction ratios from 5 to 1000. All products come with a one-year warranty from the date of delivery.

Starshine Drive: Your Trusted Power Transmission Partner

As a leading provider of power transmission solutions, Starshine Drive is dedicated to offering high-quality products and professional services. With over 350 skilled employees and advanced processing machines, we have the capabilities to meet the diverse needs of industries requiring speed reducers and variators.

Our Team

Our team consists of experienced engineering technicians and quality inspectors who ensure the highest standards of product performance and reliability.

Quality Control

At Starshine Drive, we are committed to continuous improvement and the pursuit of excellence. Our strict quality control measures include:

- Incoming Quality Control: We establish AQL acceptable levels for incoming materials and conduct thorough inspections to ensure the quality of our products.

- Process Quality Control: We closely monitor the manufacturing process and address any abnormalities to maintain consistent quality standards.

- FQC (Final QC): We conduct comprehensive inspections of finished products to verify their quality before delivery.

- OQC (Outgoing QC): We perform a final check of products before shipment to ensure they meet the expectations and needs of our customers.

Packing and Delivery

We ensure that our products are securely packed to prevent any damage during transportation. Our efficient delivery system guarantees timely and reliable shipment to our customers.

At Starshine Drive, we not only specialize in NRV Worm Geared Reducers, but also offer a wide range of industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, and bushings. We pride ourselves on providing high-quality products at competitive prices, backed by exceptional customer service. We welcome customizations based on drawings and samples to meet your specific requirements.

Frequently Asked Questions (FAQs)

- Q: Are the RV series worm gear reducers suitable for heavy-duty industrial applications?

A: Yes, the RV series is designed to handle a wide range of industrial applications, including heavy-duty operations. Their robust construction and high torque capacity make them ideal for demanding environments. - Q: Can the RV series worm gear reducers be customized to fit specific mounting requirements?

A: Yes, the RV series offers various mounting options, including input shaft, square flange, and input flange, allowing for flexible installation and compatibility with different equipment. - Q: What kind of lubrication do the aluminum units come with?

A: The aluminum units of the RV series come pre-filled with synthetic oil, eliminating the need for additional lubrication and ensuring optimal performance. - Q: Does Starshine Drive provide after-sales support for their products?

A: Yes, we offer comprehensive after-sales support, including technical assistance, warranty coverage, and spare parts availability. Our team is dedicated to ensuring your satisfaction with our products. - Q: Can I request a customized solution based on my specific power transmission needs?

A: Absolutely! We welcome customization requests based on your unique requirements. Our engineering team will work closely with you to design and deliver tailored solutions that meet your exact specifications.

All the content of this page is from the Internet and is only provided as a reference for product selection. Please note that our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you are in need of original spare parts, please contact the original factory or supplier directly for purchase.

Performance Characteristics of Worm Gear

Worm gear possesses several performance characteristics that make it highly efficient and suitable for various applications. Firstly, worm gear offers high gear reduction ratios, allowing for precise control over speed and torque. Secondly, it exhibits self-locking properties, which prevent any back-driving and enable the transmission of motion in a single direction. Additionally, worm gear provides smooth and quiet operation due to its rolling contact, reducing noise and vibration. Moreover, it has a compact design and can transmit large loads efficiently. Furthermore, it offers high efficiency in power transmission, minimizing energy loss. Lastly, worm gear is known for its durability and long service life, making it a reliable choice for different industries.

Types and Characteristics of Worm Gear

Worm gears come in various types, each with its unique characteristics. One common type is the cylindrical worm gear, which is known for its simple and cost-effective design. Another type is the double-enveloping worm gear, which offers high torque transmission and enhanced load-carrying capacity. Additionally, the globoidal worm gear provides improved contact and higher efficiency. Furthermore, the hypoid worm gear is used in applications requiring high torque and compact size. These various types of worm gears offer different performance advantages, allowing for customization based on specific requirements.

Advantages of Different Materials in Worm Gear Production

The choice of material for manufacturing worm gears greatly impacts their performance and durability. Aluminum worm gears are lightweight and corrosion-resistant, making them suitable for applications requiring low inertia. Steel worm gears, on the other hand, offer high strength and wear resistance, making them ideal for heavy-duty applications. Bronze worm gears exhibit excellent lubricity and are commonly used in applications where noise reduction is essential. Additionally, plastic worm gears are lightweight, affordable, and self-lubricating, making them suitable for low-load and low-speed applications. By selecting the right material, the performance and efficiency of worm gears can be maximized for specific operational requirements.

Application of Worm Gear in Various Fields

Worm gears find extensive application in different industries due to their versatility and reliability. In the automotive sector, worm gears are utilized in power steering systems, enabling smooth and precise steering control. In industrial machinery, worm gears are commonly found in conveyors, packaging equipment, and material handling systems, providing efficient and reliable power transmission. Lifts and elevators also utilize worm gears for their lifting mechanisms, ensuring safe and controlled vertical movement. Additionally, worm gears are used in conveyor systems to transfer goods smoothly and efficiently. Tuning devices, such as musical instrument tuners and antenna rotators, rely on worm gears for accurate adjustment. These examples highlight the value and importance of worm gears across various fields, showcasing their versatility and wide-ranging applications.

Future Development Trends and Opportunities for Worm Gear Products

The future of worm gear products holds promising opportunities for further advancements and innovations. With the ever-increasing demand for efficient power transmission, worm gears are expected to witness continuous development in terms of material enhancements, manufacturing processes, and design optimization. The incorporation of advanced materials, such as composites and alloys, may lead to improved performance and durability. Moreover, advancements in gear design and manufacturing technologies, such as 3D printing and computer-aided design, may revolutionize the production of worm gears, enabling more precise and efficient designs. The growing automation and robotics industries also present significant opportunities for the utilization of worm gears in various applications. Overall, the future of worm gear products is poised for growth and evolution, offering immense potential for continued innovation and market expansion.

Choosing a Suitable Worm Gear

Selecting the appropriate worm gear is crucial to ensure optimal performance and longevity. Several aspects need to be considered during the selection process. Firstly, the load requirements must be thoroughly analyzed to determine the necessary torque and power transmission capabilities. Secondly, the gear ratio should be carefully chosen to achieve the desired speed reduction or increase. Moreover, the material selection should align with the application’s demands, considering factors such as load capacity, wear resistance, and environmental conditions. Additionally, efficiency and backlash should be evaluated to minimize energy loss and ensure smooth operation. Lastly, mounting requirements and space constraints should be taken into account to ensure proper installation and compatibility with the existing system. By considering these aspects, a suitable worm gear can be chosen to meet specific application needs effectively.

Conclusion

In conclusion, worm gears offer a range of performance characteristics that make them a preferred choice for numerous applications. Their ability to provide high gear reduction ratios, self-locking properties, smooth operation, and efficient power transmission makes them invaluable in various industries. With different types and materials available, worm gears can be customized to suit specific requirements, further enhancing their versatility. The future of worm gear products holds immense potential for further development and advancements, presenting opportunities for growth and innovation. By carefully considering load requirements, gear ratios, material selection, efficiency, backlash, and mounting constraints, a suitable worm gear can be selected, ensuring optimal performance and longevity. Worm gears continue to play a vital role in power transmission systems, contributing to the seamless operation of machinery and facilitating progress across industries.

Author: Dream